More Products

Product tags

2 heads piston liquid filling machine

12 heads Lubricant Oil filling machine

Automatic capsules tablets counting and filling line

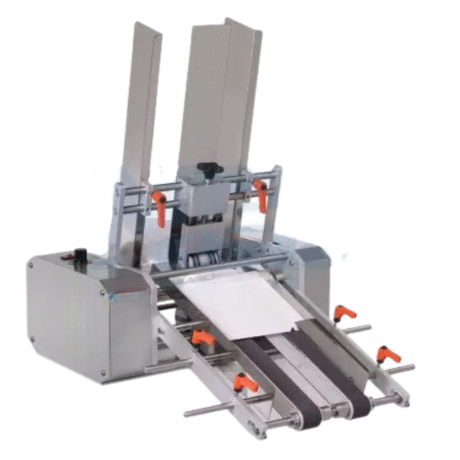

Automatic friction feeder

Automatic Tablet Counting Machine

Bag feeder

Bleach filling machine

Capsule counter

Capsule Pill Tablet Counter

Capsules tablet pills counting machine

Card feeding machine

chemical industry filling production line

Dietary supplement counter

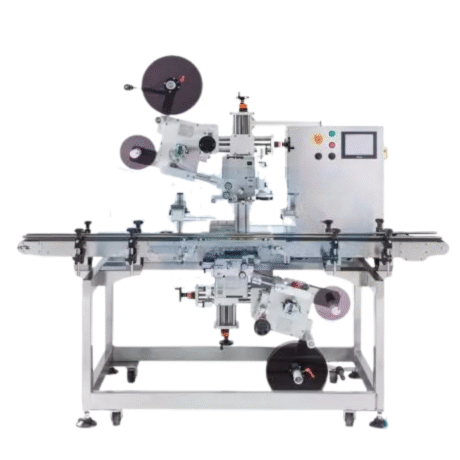

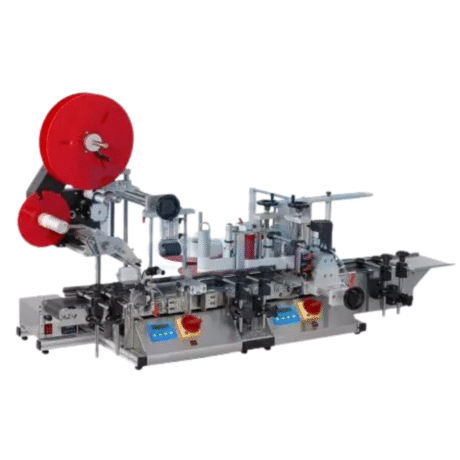

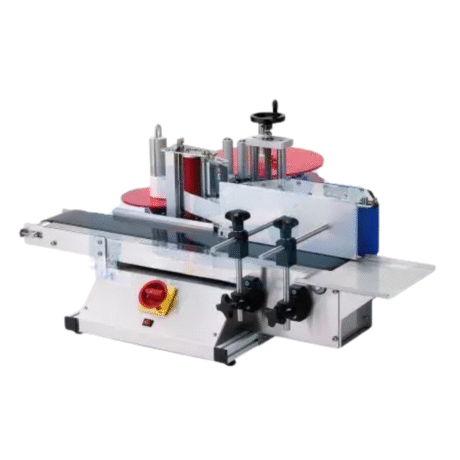

Double-Sided Labeler

Edible oil for 20 liters volume filling packaging machine

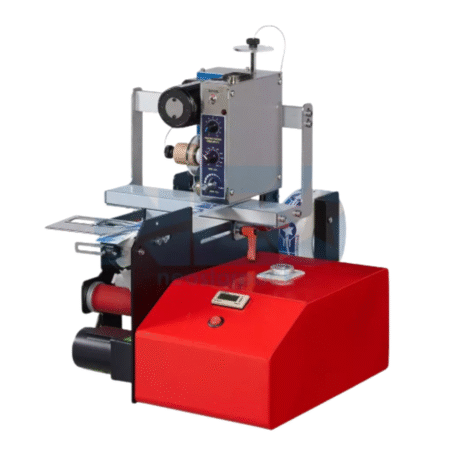

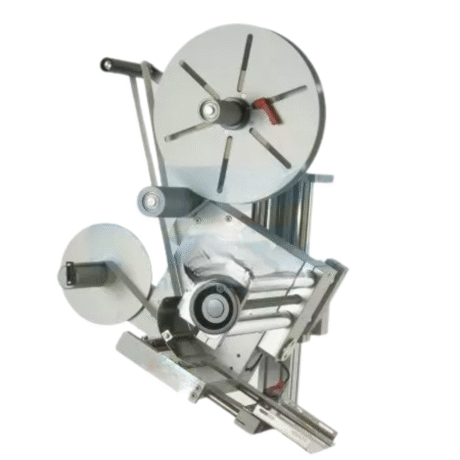

Electric label dispenser

Electric tablet capsule counter

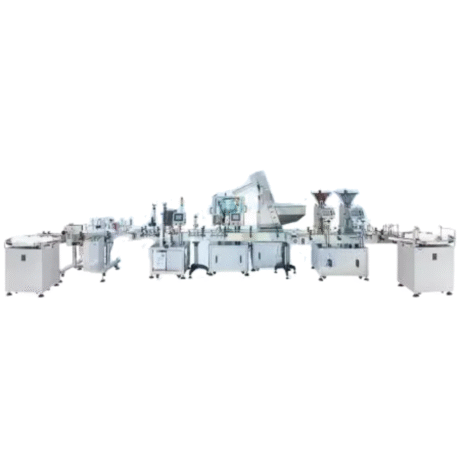

Fully filling capping labeling machine

Glass bottle labeller

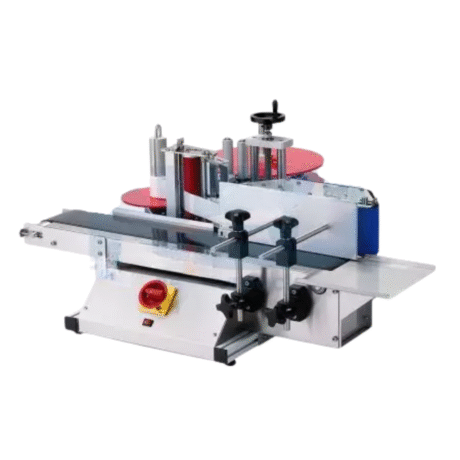

Horizontal round bottle labeling machine

Liquid detergent filler

Liquid detergent filling machine

Lubricant filling line

Lubricant oil filling machine

Mouthwash filling machine

Nutritional supplement labeller

Oil filling machine

Over-flow filling machine

Pharmaceutical counting machine

Pharmacy tablet counter

Pill counter machine

Piston liquid filler with housing

Round bottle labeling machine

Semi-automatic capsule counting machine

Simple tablet counter

Tablet capsule counting and filling machine

Tablet counting packaging machine

Tabletop round bottle labeling machine

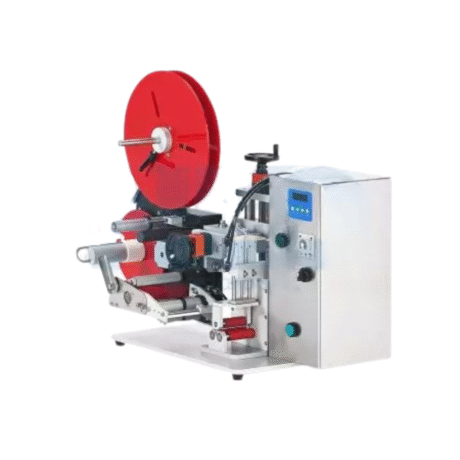

Tabletop tamp labeling machine

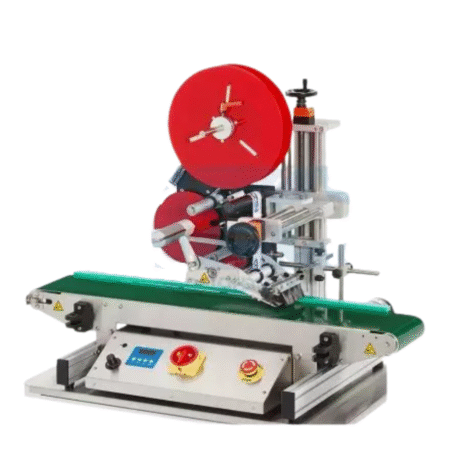

Tabletop top labeling machine

Tabletop top tamp labeling machine

Top label applicator

Two-Side Labeling Machine

Viscous liquid filling machine

Wrap around labeling machine

-

New!

-

New!

-

New!

Twelve Nozzle Automatic Lubricant Oil Filling Machine (Piston Pump)

Availability: In Stock Read more -

New!

-

New!

-

New!

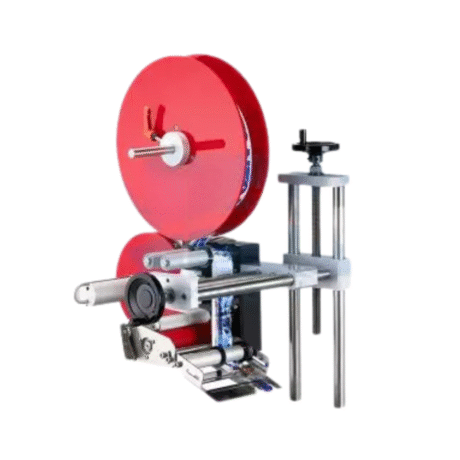

Top Label Applicator

Availability: In StockRead moreFeatures

- Driven by a stepper motor, ensures stable and accurate labeling.

- The structure of the label applicator is simple, which is suitable for setting up on various production lines, and space-saving.

- Intelligent sensor detection system, accurate labeling without missing.

- The label applicator is equipped with a back paper spool disk, which makes it convenient to remove the used back paper, saving time and manpower.

- Translucent spool disc design for quick checking of residual stickers.

- Intelligent Microcomputer Control, easy to learn the operation, one-button setup.

- Multiple memory modules: available to switch between different production lines and improve efficiency.

- The stepper motor drives the device, providing high labeling accuracy.

- The label applicator makes it easier to adjust the height, angle, and position of the conveyor and bracket according to production needs.

- Provide a flexible label applicator design to meet different labeling needs.

- It can be integrated with the PLC control system to connect production lines, improving the automation level and reducing labor costs.

- Setting the parameters through a precision label sensor, accurately detecting labels and back paper to avoid errors.

- Automatic amplifier detection: Accurately control the label length to reduce waste.

- Adjustable labeling speed: Labeling speed can match the production line speed to avoid delays.

- The conveyor speed is synchronized with the labeling speed to ensure the smoothness and consistency of the labeling.

- Intelligent Sensor Detection System: Automatically detects the product position. If there is no product, the machine won’t dispense labels.

- Precise stepper motor driving LA1100, to smoothly and quickly complete labeling tasks and increase productivity.

- Industrial-grade standard switch is durable with a long service life.

- Automatic counting function, clearly displays the labeling output, easy to take control of the production line status.

- Advanced Test Mode actively detects the status of electronic components and takes control of the operation.

- Versatility: You can choose various packaging equipment as an option, such as a verification system and a top pressing unit.

- Customized production: Install a printer bracket according to requirements, effectively utilizing production space.

- A round bottle wrapping unit or spindle wrapping unit can be chosen to meet different labeling requirements.

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!

-

New!