- Both round bottle labelers and top labelers are equipped with high-quality Japanese-made photo-electronic eyes that automatically detect applications and operate according to settings.

- The pneumatic fixed-point round labeling unit fulfills labeling tasks with great precision.

- Tabletop Wrap Around and Top Labeler is powered by fixed-speed stepper motors, providing steady labeling outputs.

- This multi-functional labeling machine is of great space efficiency, providing an outstanding bottling solution for businesses with limited workplace space.

- Tabletop Wrap Around and Top Labeler is built with parameter settings in the micro-computer program, freeing you from complicated manual parameter settings, minimizing learning duration.

- The “One machine, two ways of labeling’ feature satisfies an extensive range of labeling needs.

- Fixed-point round bottle labeler applies wrap-around and semicircle labels with high precision.

- Tabletop Wrap Around and Top Labeler has synchronized conveyor belts and labeling heads that move products with stability, apply labels with precision.

- The two labeling heads can work independently or coordinately, boosting the productivity of versatile labeling.

- The right-angle labeler contains a unique folding mechanism, which can press the label on the cap and the bottle body at the same time, and firmly applies labels on targeted positions.

- Tabletop Wrap Around and Top Labeler is provided with hand wheel adjustment tools, adjusting labeling angles and heights with ease.

- When applying different labels, the machine will automatically detect the length of the new labels through its photo-electronic eye, minimizing manual parameter settings.

- An optional material receiver plate and date imprinting machine could be added to optimize productivity.

- Tabletop Wrap Around and Top Labeler is made of SUS#304 stainless steel and high-quality aluminum alloy; comes in solidity and durability.

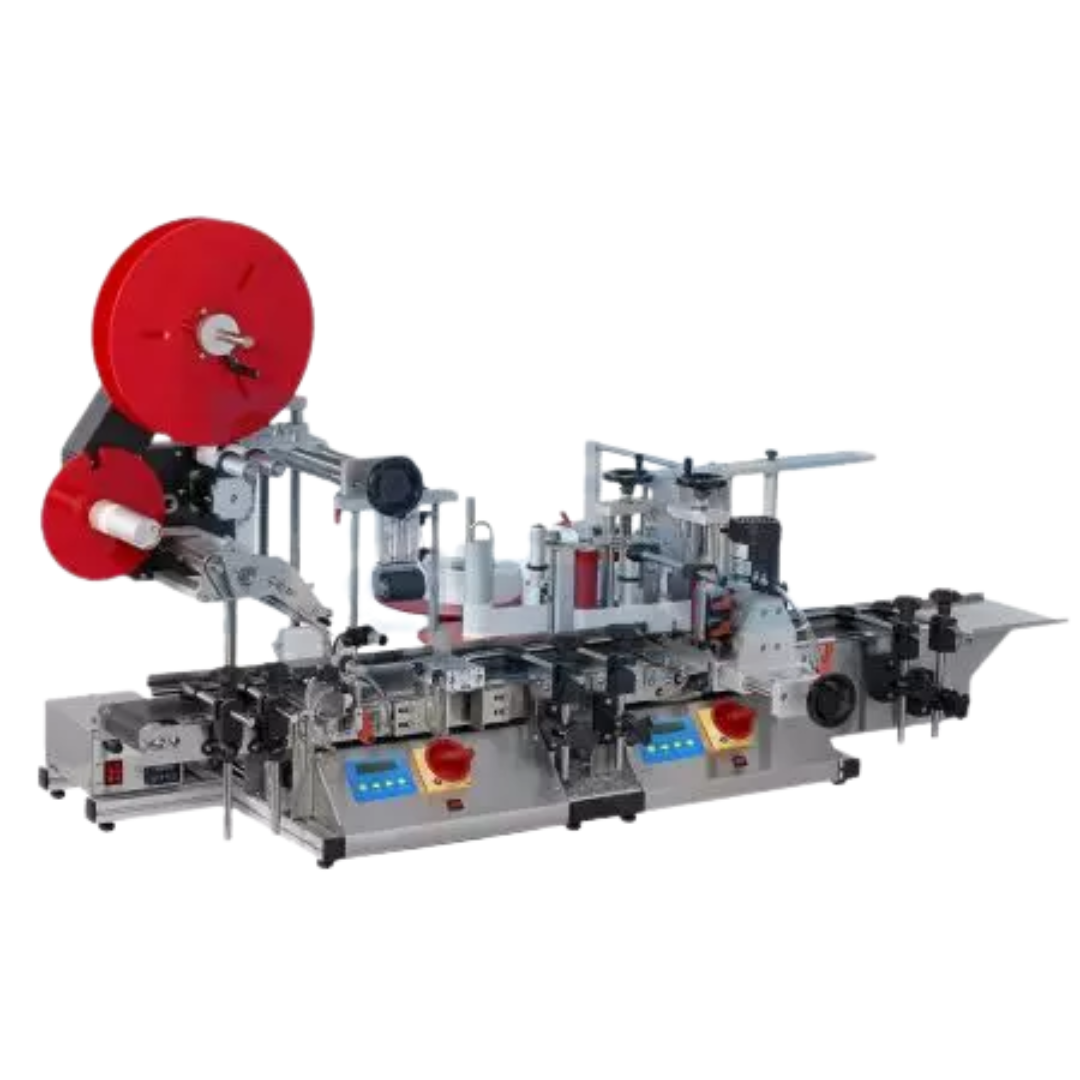

Tabletop Wrap Around and Top Labeler

- Powered by stepper motors

- Labeling Speed: 20-50 pcs/min (depending on your specific products and label sizes)

- Applicable bottle size: Diameter 16mm - 100mm; Height 30mm - 160mm

- Applicable Label Width/Length: 10 mm - 100 mm / 10 mm - 300 mm

- Label Roll: Inside 75mm; Outside 300mm

- Power Input: 110/220 VAC, 50/60 Hz

- Dimensions: (L) 1620mm (W) 950 mm (H) 810 mm

- Photoelectronic eye for transparent labels

- Automatic bottle feeding machine/receiving machine

- Date coding machine

Tabletop Wrap Around and Top Labeler is equipped with a round bottle labeling head and a top labeling head. Tabletop Wrap Around and Top Labeler fulfills labeling tasks of round bottles and top labels through a single process. Its greatest advantage is its capacity to carry out the two labeling tasks within one single process.

Its fixed-point round bottle labeler can either apply wrap-around or semicircle labels on a single or two sides of round bottles with high accuracy and within a minimal error range. The labeling speed of the tabletop wrap-around and top labeler is 20 – 50 pcs/min, depending on your specific products or label sizes.

One Labeling Machine, Two Ways Of Labeling

Tabletop Wrap Around and Top Labeler is powered by stepper motors with fixed-speed drives. Its conveyor belt is synchronized with its two labeling heads, which can either work independently or coordinately, through which the tabletop wrap-around and top labeling machine can fulfill the tasks of round bottle labeling and flat labeling in one single process.

Tabletop Wrap Around and Top Labeler applies to round bottles made of all kinds of materials and those with top labeling. Its applications include body lotion bottles, essence bottles, wine bottles, perfume bottles, nail polish bottles, ice cream buckets, lipstick cases, nutrition supplement bottles, chicken extract bottles, detergent bottles, and shampoo bottles etc.

Tabletop Wrap Around and Top Labeler applies standard labels, promotional labels, and anti-counterfeit labels (optional photoelectronic eye for transparent labels is available). It works with products of a wide range of industries such as cosmetics, pharmaceuticals, IT, food, and the chemical industry. Therefore, the tabletop wrap-around and top labeler NLR-130 + NLT-100 is the best solution for businesses with only limited workplace space but with versatile labeling needs.

Features

- Both round bottle labelers and top labelers are equipped with high-quality Japanese-made photo-electronic eyes that automatically detect applications and operate according to settings.

- The pneumatic fixed-point round labeling unit fulfills labeling tasks with great precision.

- Tabletop Wrap Around and Top Labeler is powered by fixed-speed stepper motors, providing steady labeling outputs.

- This multi-functional labeling machine is of great space efficiency, providing an outstanding bottling solution for businesses with limited workplace space.

- Tabletop Wrap Around and Top Labeler is built with parameter settings in the micro-computer program, freeing you from complicated manual parameter settings, minimizing learning duration.

- The “One machine, two ways of labeling’ feature satisfies an extensive range of labeling needs.

- Fixed-point round bottle labeler applies wrap-around and semicircle labels with high precision.

- Tabletop Wrap Around and Top Labeler has synchronized conveyor belts and labeling heads that move products with stability, apply labels with precision.

- The two labeling heads can work independently or coordinately, boosting the productivity of versatile labeling.

- The right-angle labeler contains a unique folding mechanism, which can press the label on the cap and the bottle body at the same time, and firmly applies labels on targeted positions.

- Tabletop Wrap Around and Top Labeler is provided with hand wheel adjustment tools, adjusting labeling angles and heights with ease.

- When applying different labels, the machine will automatically detect the length of the new labels through its photo-electronic eye, minimizing manual parameter settings.

- An optional material receiver plate and date imprinting machine could be added to optimize productivity.

- Tabletop Wrap Around and Top Labeler is made of SUS#304 stainless steel and high-quality aluminum alloy; comes in solidity and durability.

Specification

- Powered by stepper motors

- Labeling Speed: 20-50 pcs/min (depending on your specific products and label sizes)

- Applicable bottle size: Diameter 16mm – 100mm; Height 30mm – 160mm

- Applicable Label Width/Length: 10 mm – 100 mm / 10 mm – 300 mm

- Label Roll: Inside 75mm; Outside 300mm

- Power Input: 110/220 VAC, 50/60 Hz

- Dimensions: (L) 1620mm (W) 950 mm (H) 810 mm

Option Accessories

- Photoelectronic eye for transparent labels

- Automatic bottle feeding machine/receiving machine

- Date coding machine