- Grand full-colored touch screen: Loaded with both Mandarin and English system interfaces. User user-friendly interface that is suited for all regions.

- Intelligent control system: Automatically raises the alarm if a labeling is missed, labeling stops, or labels rip, to ensure the production process will not be interrupted.

- Flexible labeling mode: The Microcomputer can control to label single-sided or double-sided and supports single-sided labeling to satisfy multiple needs.

- Stable bottle fixing device: The special bottle fixing device stabilizes infeed bottles to ensure accurate labeling.

- Highly efficient servo motors: Adopting known Japanese corporations’ advanced servo motors to label fast and increase production efficiency.

- High safety specification: Meets the requirements of UL and CE, with a safe human-machine control interface.

- Precise sensor detection: Sensors detect accurately to swiftly locate the bottles and ensure the labeling is done without a flaw.

- Automatic label length detection: Detects the label length with a click. The function raises working efficiency effortlessly.

- High standard conveyor: Adopting a conveyor that meets the food hygiene standard, MCC. The conveyor is both durable and hygienic, with industrial, high wear resistance.

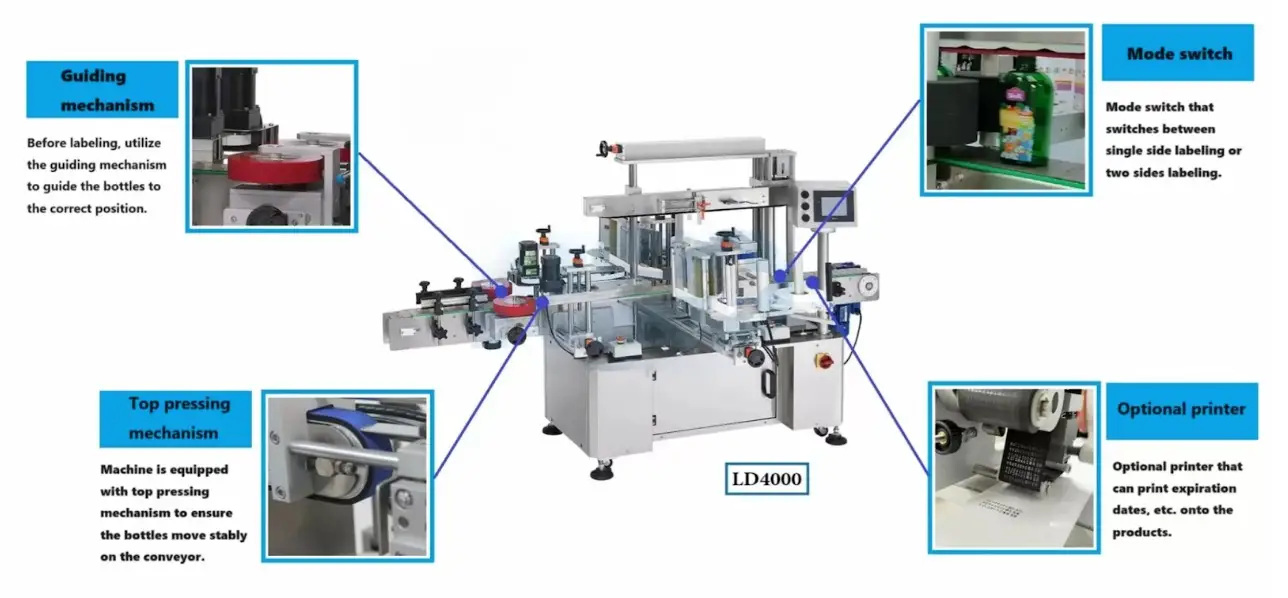

- Bottle guiding system: Automatically guides the bottles to the labeling position to ensure each labeling is accurate and precise.

- Automatic spacing device: Fixes the gap between the bottles to stabilize the bottles and increase labeling precision.

- Two-label head design: The labelers may adjust their angles slightly, targeting different product heights and angles, making the change of production lines faster than ever.

- Dynamic top pressing system: Move the bottles in sync to enhance the stability of the bottles and ensure the labeling result.

- Pressing sponge rollers: Gently flatten the labels, keep the original shape of the products, and do not press them.

- Modular design: Arrange the assembly of machines based on the products. Satisfying diverse requirements while standardizing specifications and designs.

- PLC control system: Touch screen human-machine interface, the screen itself is the interface. Humanized design, easy to understand and use.

- Stainless steel stand: Circular design to save space, and the linear design allows convenient maintenance.

- Electronic control unit: Simplifies parameter settings; anyone may operate the machine with short-term training.

- Two base designs: Fixed foot and moving roller wheels design, allowing easy and convenient machine transfer.

- Label counting function: Monitor the production line status in time, and the label counts will show on the screen.

- Adjustable guide rails: Adjust the guide rails based on the product size. The guide rails are smooth and will not damage the products when conveyed.

- Quick handle adjuster: Equipped with a handle adjusting function that can adjust in both vertical and horizontal directions.

- Linkage design: The conveyor and labeling speed are synced when adjusting, raising the working efficiency.

- Refined sponge device: The labels stick tightly to the products, ensuring the perfect labeling without bubbles.

- High cleanliness machines: Meets the requirements of a Class-10000 clean room and satisfies the needs of the electronics industry.

- High-rank material made: Host machines, docks, stands, conveyor mechanisms, etc., are all crafted with high-rank stainless steel SUS304 and hardened aluminum alloy that are durable and require minimal maintenance.

High Speed Front and Back Labeler

- Degree of Automation: Fully Automatic

- Motors Spec: Servo Motors

- Premium Conveyor: 200mm, can be customized.

- Product Applicable Size: Diameter: 20 mm- 125 mm, Height: 30-160 mm

- Labeling Speed: 40-100 pcs/min (Varies to product and label sizes)

- Label Size: (Width) 10-100mm, (Length) 20-300mm

- Label Roll Internal Diameter: 75mm, Exterior Diameter: 300mm

- Power Supply Requirements: 110 or 220VAC, 50/60Hz Single phase

- Machine Size: (L)2100mm x (W)1380mm x (H)1500mm

- PLC HMI system

- Infeed/Outfeed Turntable

- Dedicated Sensor for transparent labels

- Parts such as Brushes and Sponge Rollers that can flatten the labels

- Feeding and Discharging Platform: Motor-driven feeding and discharging turntable

- Expiration Date Printers, Laser Printers, and Inkjet Printers.

- Pneumatic Fixed Point Wrapping Unit: Suited to label 3/4 to the whole bottle, bottles that require high precision.

Machine Advantages

Multiple features labeling mode

With a two-label-head design and curve surface labeling feature, Applicable for curved products to ensure the labels stick tightly and do not peel easily.

Increased production efficiency

Complete front and back labeling with one single operation.

Highly efficient advanced motors

Adopting high-rank motors that enable the machine to label up to 100 products per minute. Fast, accurate, and greatly increased the production efficiency.

Calibration mechanism and spacer module

The calibration mechanism will guide products to the proper position while the spacer module will fix the gap between bottles to reduces flaws

Applicable Products

Canned food, beverage bottles, condiment bottle, food packaging bags, plastic boxes, food retort pouch, oil bottle, yogurt, juice, bottled honey, bagged coffee beans, pepper, egg, egg cartons, whiskey, wine bottles, syrup, mayonnaise, ketchup, mustard, tea preservation bag and energy drinks.

Shampoo bottles, cream bottles, cosmetic bottles, mouthwashes, shower gel bottles, hair dyes, mosquito repellent, hand wash, perfume, toothpaste and makeup organizer.

Vials, pill box, medical equipment package, medicine boxes, and nutrition supplements.

Pet shampoo, detergent bottles, laundry detergent bucket, sanitizer, industrial oil barrel, pesticide bottles, engine oil bottles, lubricants, paint buckets, reagent bottles, and industrial adhesives.

SD cards, paper cards, credit cards, paperboard boxes, DDR modules, tool organizer boxes, metal boxes, electronic components, and plastic films.

Folders, notebooks, paper boxes, plastic boxes, tags, and paper bags.

Applicable product shape:

- Flat products: Such as boxes, bags, or books, products with flat front and back sides.

- Cylindrical products: Such as bottles, cans, or barrel-like containers.

- Square products or containers: square bottles, square barrels and packaging boxes.

- Containers with a slight curve on the sides: Oval bottles, flat bottles, and polygonal bottles.

Applicable product materials:

- Plastic: Including PET, PE and PVC, etc.

- Glass: Transparent or colored glass containers, etc.

- Metal: Aluminum, iron, copper and stainless steel.

- Fiberboard: Such as MDF or hard cardboard and special packaging needs.

- Composite materials: Combination of multiple materials’ characteristics, such as the combination of plastic film and paper.

- Paper and Ceramic

Applicable Labels:

Adhesive labels, paper labels, tamper resistant labels. security labels, void labels, fragile stickers, ingredient list labels, waterproof labels, anti-counterfeit label, synthetic materials labels: such as polyester or polypropylene labels, nutrition labels, thermal labels, freezer labels, heat- resistant labels, reflective label, biodegrade labels, beer labels and transparent labels.

Labeling Method:

- Product detection: The Sensor will automatically detect the products that enter the labeling machine and start the labeling process.

- Front and back labelers: Two label heads handle the front and the back label, respectively, ensuring the labels stick accurately.

- Pressure-sensitive labeling: The machine adopts the pressure-sensitive method to label the products.

- Speed spacers: Align the products to label them smoothly.

- Brush smoothing: After labeling, the brush will smooth the labels to ensure they are well-attached.

- Conveyor transport: Labeled products will be sent to the next station and can be integrated with printers or product receiving equipment.

Applicable Industries:

Pharmaceutical, food and beverage, chemical, electronics, clothing and textile, biotechnology, household chemicals, cosmetics, and toy industries.

Machine Layout:

High Speed Front and Back Labeler LD4000 is designed to increase production efficiency and accuracy, being capable of accurately labeling on both the front and the back side of the products. They are suited for various industries and products, even bottles with curved sides can be labeled accurately with ease.

A special two-label-head design that can work independently or together to label two labels simultaneously with high speed, significantly decreasing the time required to infeed bottles and increasing productivity. High Speed Front and Back Labeler LD4000 maintains labeling speed and accuracy by adopting high-rank motors and ensures that each product can be labeled perfectly.

Furthermore, the vertical type labeling mode of High Speed Front and Back Labeler LD4000 expands the already wide application range, no matter whether it is a flat or curved side, the labels stick tightly and do not peel easily; the built-in intelligent microcomputer control system is capable of monitoring the labeling process and raise the alarm in time when missed a label or when a label rips to ensure the consistency and fluency of the production process.

Built for mass production, Front & Back Labeler LD4000 meets the need for faster and more

Accurate labeling with its exceptional performance.

High Speed Front and Back Labeler LD4000 provides excellent labeling methods for various industries with exceptional performance. The difference between LD3000 and LD4000 is that the latter is equipped with high-rank motor technology to reach faster labeling speed and higher production efficiency, making them even more competitive.

The elaborately designed High Speed Front and Back Labeler LD4000 is capable of labeling at the default position through a refined sensor system when the product containers pass through the conveyor. F

or corporations that need mass bottle labeling production, the consistency and accuracy of end product labels will help raise the products’ professional appearance.

With multiple feature designs, operators may quickly swap the products and labels without changing any of the parts as long as it’s within the specification range, providing the manufacturer with great flexibility.

High efficiency automatic labeling production line: Professionally customized solution

The simplicity of High Speed Front and Back Labeler LD4000’s operations made education training easier and faster, saving significant time and costs.

High Speed Front and Back Labeler LD4000 is capable of providing diverse optional and special components, as well as the option to integrate with other packaging equipment to build a fully automatic production line, meeting both the needs of speed and accuracy.

High Speed Front and Back Labeler LD4000 not only raised the labeling efficiency and quality but also provided industries with a flexible and reliable labeling solution.

Features

- Grand full-colored touch screen: Loaded with both Mandarin and English system interfaces. User user-friendly interface that is suited for all regions.

- Intelligent control system: Automatically raises the alarm if a labeling is missed, labeling stops, or labels rip, to ensure the production process will not be interrupted.

- Flexible labeling mode: The Microcomputer can be controlled to label single-sided or double-sided and supports single-sided labeling to satisfy multiple needs.

- Stable bottle fixing device: The special bottle fixing device stabilizes infeed bottles to ensure accurate labeling.

- Highly efficient servo motors: Adopting known Japanese corporations’ advanced servo motors to label fast and increase production efficiency.

- High safety specification: Meets the requirements of UL and CE, with a safe human-machine control interface.

- Precise sensor detection: Sensors detect accurately to swiftly locate the bottles and ensure the labeling is done without a flaw.

- Automatic label length detection: High Speed Front and Back Labeler detects the label length with a click. The function raises working efficiency effortlessly.

- High standard conveyor: Adopting a conveyor that meets the food hygiene standard, MCC. The conveyor is both durable and hygienic, with industrial, high wear resistance.

- Bottle guiding system: High Speed Front and Back Labeler automatically guides the bottles to the labeling position to ensure each labeling is accurate and precise.

- Automatic spacing device: Fixes the gap between the bottles to stabilize the bottles and increase labeling precision.

- Two-label head design: The labelers may adjust their angles slightly, targeting different product heights and angles, making the change of production lines faster than ever.

- Dynamic top pressing system: Move the bottles in sync to enhance the stability of the bottles and ensure the labeling result.

- Pressing sponge rollers: Gently flatten the labels, keep the original shape of the products, and do not press them.

- Modular design: Arrange the assembly of machines based on the products. Satisfying diverse requirements while standardizing specifications and designs.

- PLC control system: Touch screen human-machine interface, the screen itself is the interface. Humanized design, easy to understand and use.

- Stainless steel stand: Circular design to save space, and the linear design allows convenient maintenance.

- Electronic control unit: Simplifies parameter settings; anyone may operate the machine with short-term training.

- Two base designs: Fixed foot and moving roller wheels design, allowing easy and convenient machine transfer.

- Label counting function: Monitor the production line status in time, and the label counts will show on the screen.

- Adjustable guide rails: Adjust the guide rails based on the product size. The guide rails are smooth and will not damage the products when conveyed.

- Quick handle adjuster: High Speed Front and Back Labeler equipped with a handle adjusting function that can adjust in both vertical and horizontal directions.

- Linkage design: The conveyor and labeling speed are synced when adjusting, raising the working efficiency.

- Refined sponge device: The labels stick tightly to the products, ensuring the perfect labeling without bubbles.

- High cleanliness machines: High Speed Front and Back Labeler meets the requirements of a Class-10000 clean room and satisfies the needs of the electronics industry.

- High-rank material made: Host machines, docks, stands, conveyor mechanisms, etc., are all crafted with high-rank stainless steel SUS304 and hardened aluminum alloy that are durable and require minimal maintenance.

Specifications

- Degree of Automation: Fully Automatic

- Motors Spec: Servo Motors

- Premium Conveyor: 200mm, can be customized.

- Product Applicable Size: Diameter: 20 mm- 125 mm, Height: 30-160 mm

- Labeling Speed: 40-100 pcs/min (Varies to product and label sizes)

- Label Size: (Width) 10-100mm, (Length) 20-300mm

- Label Roll Internal Diameter: 75mm, Exterior Diameter: 300mm

- Power Supply Requirements: 110 or 220VAC, 50/60Hz Single phase

- Machine Size: (L)2100mm x (W)1380mm x (H)1500mm

※ Dimensions may vary based on configurations; actual specifications are subject to the machine received.