- No air compressor is needed, nor the loud noise from it when running. Improving the comfort in the working environment, best suited for hospitals and clinics.

- The counting number can be freely set from 5 to 2500, using a button to set it, easily and conveniently.

- Equipped with a refined photoelectric sensor counting system, the high precision counting ensures each subpackaging number is correct.

- Vibrating discharge control can prevent the tablets from being stuck, and you may adjust the discharge speed based on products or your needs.

- Dual filling nozzles rotate the discharge and produce without stopping. More user-friendly for the two-hand operation design, raising production efficiency.

- Commonly applied to pharmacies, hospitals, food industries, pharmaceutical manufacturers, and laboratories, etc., for capsules, tablets, pills, and pellets, etc., to count, bottle, or package.

- Smart control features with a user-friendly interface. The vibration frequency can be adjusted based on different product types to accommodate different product requirements with flexibility and greatly increase production efficiency.

- Set the counting number with only one click; no tools are needed to change the bottles. The quick-release structure makes changing products easy. You do not need any professional training to be able to pick up the machine with ease.

- Requires only electricity to use, no air required, and no more noise from air compressors.

- Compact size to utilize the limited production space to its fullest potential.

- Turning knob control vibration system that can be adjusted with flexibility based on the target product’s diameter to ensure the maximum production capacity is reached.

- Strict quality control and test processes to ensure each machine can run stably for the long term.

- An automatic subpackaging system to reduce the workforce needed to operate the machine and raise the production efficiency.

- Strictly follow health standards to ensure the production process meets the industry regulations so that the products are safe and hygienic.

- Its advanced technology and stable performance make it vital equipment for various industries to raise production efficiency and improve competitiveness.

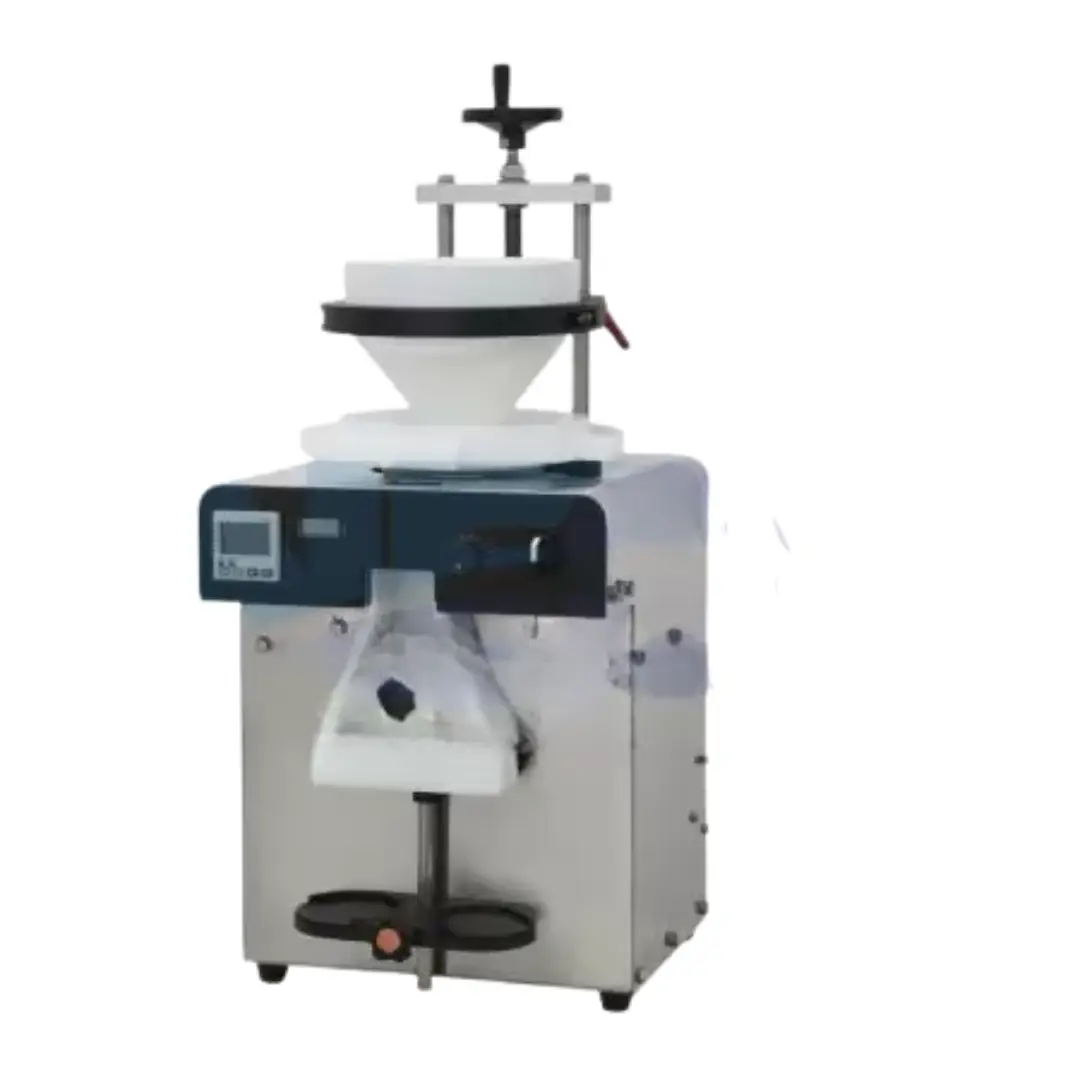

Compact Tablet Counter mTC1000

- Degree of Automation: Semi-automatic

- Tablet Size: (Length) 10 mm~25 mm;(Height)>2mm NO.000~NO.5

- Counting Speed: 400~600 pcs/min (Varies based on tablet size and shape)

- Counting Precision: 100%

- Applicable Bottles: (Diameter) 25mm~60mm;(Height) 40-140mm

- Power Supply: 110 or 220 VAC, 50/60Hz, single phase

- Machine Size:(L)360mm (W)300mm (H)670mm

- *Actual machine size may vary; the machine size to subject to the actual machine.*

- Bottle Jig

- Dust Cover

- Trolley

The compact tablet counter is dedicatedly designed to count and subpackage tablets, capsules, and other solid medicines.mTC1000 is a small tablet counting equipment designed for pharmacies, hospitals, laboratories, and other small-scale manufacturers.

Compact Tablet Counter mTC1000 is compact and easy to operate, capable of counting and subpackaging medicines such as tablets, hard capsules, pills, and lozenges, or health supplements and food into bottles or bags.

Compact Tablet Counter mTC1000 is known for its high efficiency, easy-to-operate design, high accuracy counting, and it is capable of counting around 600 tablets per minute. This makes it best suited for small- to medium-scale manufacturing, providing an efficient and stable production method.

No need to adjust for different products, count various tablets and capsules with ease.

Compact Tablet Counter mTC1000 is capable of handling tablets, capsules, and pills of various sizes and shapes. It is suitable for products with a diameter of 6 mm, a thickness of 3 mm, and the above.

Not only those, it is also not a stranger to soft and hard capsules, tablets, pills, pellets, sugar-coated pills, buccal tablets, mint tablets, and chewing gums that are consistent in shape and are not sticky. The mTC1000 does not need a complicated adjustment to be able to count the products; it is flexible and convenient.

High-Efficient Dual-Track System to Increase Production Capacity and Accuracy.

Compact Tablet Counter mTC1000 equipped with dual tracks that can discharge tablets continuously and dual filling nozzles to subpackage two bottles at the same time, the mTC1000 is user-friendly, highly efficient for its two-handed operation design.

Compact Tablet Counter mTC1000’s counting speed can be adjusted based on product and production requirements. Paired with the rapid discharge device, it will not slow down or have tablets stuck inside when counting.

The product feeding speed can be adjusted directly by the knob based on the product type to reach a stable production capacity. It is an easy-to-operate small counter that requires no tools when changing the containers, and it also requires no special training to use; one person is all you need to complete all of the operations.

This highly cost-worthy tablet counter not only can raise production efficiency, require no air compressor, but can also utilize the space effectively, making it the top choice for small and medium pharmacies and health supplement manufacturers.

Our Advantages:

- Small and compact design: Phenomenal space efficiency, all you need is a small, flat surface to set up a production line, making it easier to plan circulation within limited space.

- Multifunctionality: Compact Tablet Counter mTC1000 is applicable to tablets and pills with diverse sizes and shapes.

- High Precision Counting: Sophisticated detection counting, same amount of tablets per bottle, ensuring production consistency.

- High-Efficiency Production: Dual discharge design to cross-fill continuously, greatly increasing subpackaging efficiency.

- Stable Performance: Counts 150 to 200 tablets per minute (Based on tablet size) and automatically sub packages them.

Applicable Products:

- Pharmaceutical: Compact Tablet Counter mTC1000 can count medicines such as tablets, pills, soft capsules, etc. Ensuring the dosages are correct across the bottles or packages so that the patient can take with medication safely and follow the drug regulations.

- Biotechnology: Health supplement companies often utilize tablet counters to count health supplements or vitamins in the form of capsules or pills, such as herbal supplements, various vitamins, minerals, fish oil, amino acids, and protein supplements.

- Food & Beverage: Can be applied to count small pieces of food such as Candy, sugar-coated pills, chocolate balls, chewable supplements, mints, lozenges, or functional food in the form of tablets and capsules, or any other edible products that need precise packaging.

- Cosmetics: Compact Tablet Counter mTC1000 is suitable for beauty and cosmetics industries with products such as beauty care products, essence, capsules, skin-care capsules, beauty-assist vitamins, hair-care capsules, and beauty essence capsules, etc.

- Chemicals: Main Application: Some chemicals in the form of tablets or pellets that require precise counting and subpackaging, such as chemical cleaning tablets, clothes washer capsules, laboratory reagents, etc.

- Veterinarian: Main Purpose: To dispense medicines precisely for animals of various types in the field of veterinary. Countable products: animal medicines, vitamins, and pet health supplements.

Applicable Industries:

Pharmaceutical factories, biotechnology companies, health supplement manufacturers, cosmetics, food factories, laboratories, hospitals, pharmacies, and clinics.

Packaging Method:

Plastic bottles, glass containers, and package bags.

Applicable Product Types:

Hard capsules, soft capsules, pills, circular tablets, oval tablets, tablets, pellets, heart-shaped tablets, diamond-shaped tablets, triangle tablets, polygon tablets, and irregular-shaped tablets.

Layout:

Features

- No air compressor is needed, nor the loud noise from it when running. Improving the comfort in the working environment, best suited for hospitals and clinics.

- The counting number can be freely set from 5 to 2500, using a button to set it, easily and conveniently.

- Equipped with a refined photoelectric sensor counting system, the high precision counting ensures each subpackaging number is correct.

- Vibrating discharge control can prevent the tablets from being stuck, and you may adjust the discharge speed based on products or your needs.

- Dual filling nozzles rotate the discharge and produce without stopping. More user-friendly for the two-hand operation design, raising production efficiency.

- Compact Tablet Counter mTC1000 is commonly applied to pharmacies, hospitals, food industries, pharmaceutical manufacturers, and laboratories, etc., for capsules, tablets, pills, and pellets, etc., to count, bottle, or package.

- Smart control features with a user-friendly interface. The vibration frequency can be adjusted based on different product types to accommodate different product requirements with flexibility and greatly increase production efficiency.

- Set the counting number with only one click; no tools are needed to change the bottles. The quick-release structure makes changing products easy. You do not need any professional training to be able to pick up the machine with ease.

- Requires only electricity to use, no air required, and no more noise from air compressors.

- Compact Tablet Counter mTC1000’s compact size is to utilize the limited production space to its fullest potential.

- Turning knob control vibration system that can be adjusted with flexibility based on the target product’s diameter to ensure the maximum production capacity is reached.

- Strict quality control and test processes to ensure each machine can run stably for the long term.

- An automatic subpackaging system to reduce the workforce needed to operate the machine and raise the production efficiency.

- Strictly follow health standards to ensure the production process meets the industry regulations so that the products are safe and hygienic.

- Compact Tablet Counter mTC1000’s advanced technology and stable performance make it vital equipment for various industries to raise production efficiency and improve competitiveness.

Specification

- Degree of Automation: Semi-automatic

- Tablet Size: (Length) 10 mm~25 mm;(Height)>2mm NO.000~NO.5

- Counting Speed: 400~600 pcs/min (Varies based on tablet size and shape)

- Counting Precision: 100%

- Applicable Bottles: (Diameter) 25mm~60mm;(Height) 40-140mm

- Power Supply: 110 or 220 VAC, 50/60Hz, single phase

- Machine Size:(L)360mm (W)300mm (H)670mm

- *Actual machine size may vary; the machine size to subject to the actual machine.*

Option Accessories

- Bottle Jig

- Dust Cover

- Trolley