- Automatic Filling and Capping Machine Line is equipped with a threaded-rod conveying device that makes bottle transport more stable and consistent.

- Multiple nozzles, a dual-track liquid filling machine keeps you from wasting time on bottle positioning, and it saves your filling time, which can improve capacity.

- Automatic Filling and Capping Machine Line's gear pump used on the filling machine meets the hygiene regulations.

- The Module on the instrument can be customized to apply to different bottles.

- Automatic Filling and Capping Machine Line's filling volume is adjustable, depending on the bottle capacity and bottle mouth diameter.

- Automatic Filling and Capping Machine Line's memory function lets you save and load the parameter setting easily, simple to do product changeover simple.

- Automatic Filling and Capping Machine Line's filling nozzle is made of stainless steel, and it has a special ball valve that can prevent liquid dripping.

- Automatic filler capper machine equipped with a high-accuracy Big brand sensor, lowers the false detection possibility.

- The machine interface is user-friendly, simple to operate, and can adjust the filling volume and production speed.

- The liquid filling machine is equipped with a dripping-free device under the filling nozzle, avoiding liquid dripping.

- The diving filling nozzle prevents foam from forming when liquid filling.

- Automatic Filling and Capping Machine Line has a flow sensor and a liquid level detection sensor that provide stable filling speed and precise liquid output.

- The cap-sorting, cap-feeding, and cap-placing machine can be customized (for special caps)

- Oval round bottle liquid filling capping machine can be applied to room temperature and low viscosity liquid filling production.

- The capping machine has a no-cap and no-bottle reminder so the operator can monitor the production on time.

- The Automatic Filling and Capping Machine Line has a production capacity counting function that can be used for quantity statistics and daily capacity analysis.

- The filling tube meets the food, pharmaceutical, and biotech industry requirements; there will be no interaction between the tube and liquid.

- The Automatic Filling and Capping Machine Line is easy to adjust and has a precise control system.

- The special vacuum valve can be applied to low to medium-concentration liquid filling.

- Automatic Filling and Capping Machine Line's Automatic shut-off valve ensures the surplus liquid will flow into the storage tank, and no other recycle equipment is needed.

- Automatic capping machine can use different capping modes according to the cap types and bottle shapes you use.

- Both filling head and capping head are equipped with a hand wheel and a position indicator, which can help the operator to adjust the machine and record the data.

- Automatic Filling and Capping Machine Line has a multi-speed motor-driven conveyor whose speed can be adjusted depending on production requirements.

- The modularized design makes it easy to maintain and can be replaced according to your needs.

- The Automatic Filling and Capping Machine Line is controlled by a PLC, and its counting function ensures the production process.

- The filling line is modularized and can be updated on demand, increasing the production flexibility.

- The whole machine (Automatic Filling and Capping Machine Line) is made of stainless steel and hardened aluminum alloy, which is solid and lasting

- Adjustable base frame and moving wheel.

- The automatic bottle in-feed and out-feed machine can upgrade the line into full automatic production, reducing the manpower requirement.

- Automatic bottle unturned and bottle jam detection function.

Automatic Filling and Capping Machine Line

- Filling speed: Max. 250ml/sec

- Filling range: Max. 5000ml

- Dimension: (L) 2800mm (W) 1500mm (H) 2400mm

- Weight: 560 KG

- Cap types: common screw caps

- Cap diameter: 25-55mm

- Capping speed: 30-45BPM (depends on the bottle and cap type)

- Dimension: (L) 2500mm (W) 1200mm (H) 1600mm

- Weight: 450 KG

- Power: 110/220 VAC, 50/60, 1Phase

- Air: 80 PSI/ 3CFM

- Round bottle labeler

- Bottle outfeed machine

- Temperature-proof and abrasion-proof tubes are available

- Automatic bottle infeed machine

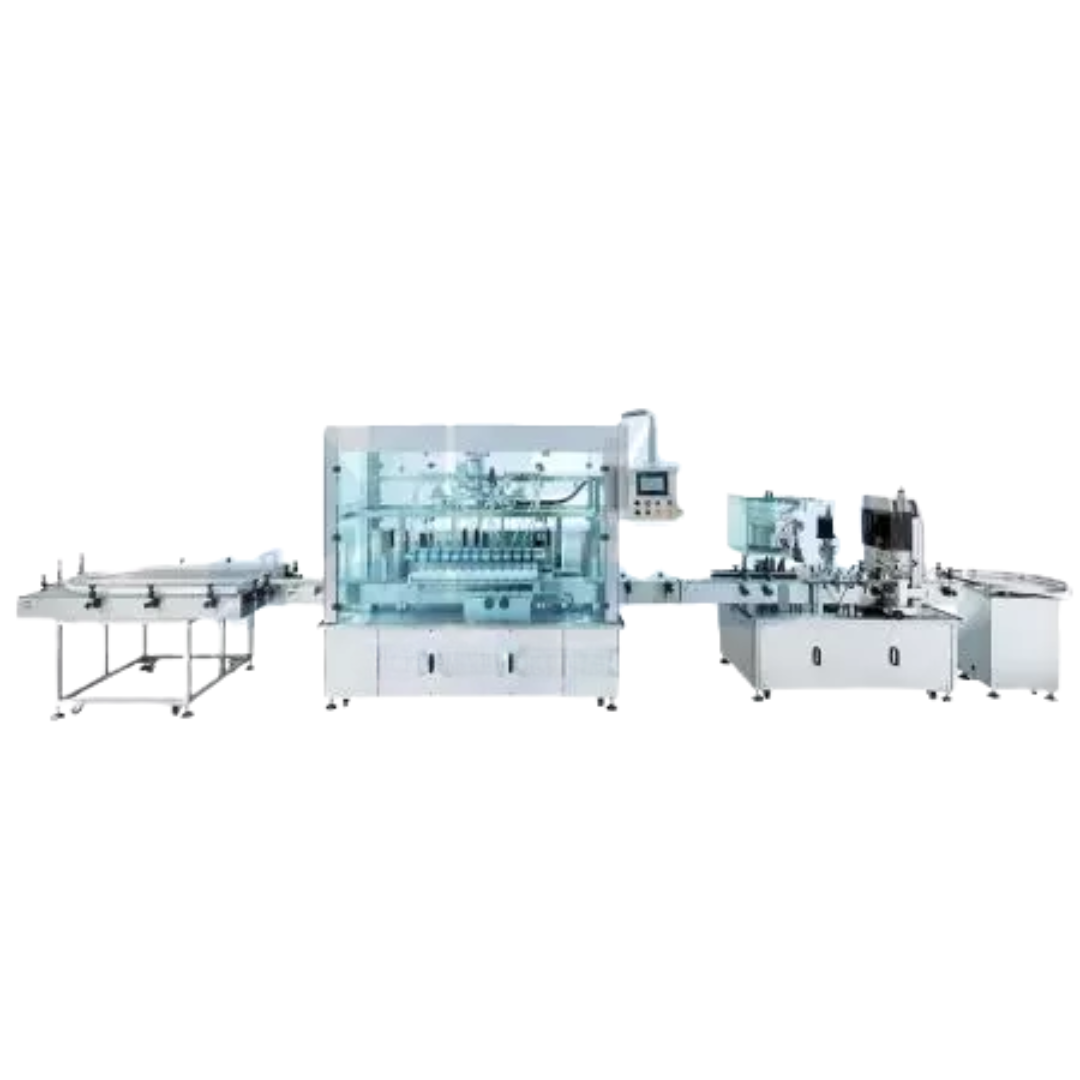

Automatic Filling and Capping Machine Line (overflow filler) can do automatic bottle feeding, automatic liquid filling, automatic cap feeding, cap placing, cap screwing and automatic bottle out-feeding procedure, and the machine can be applied to round and oval round bottle container that usually be used on daily cleaning supplies such as shampoo, shower gel, moisturizing cream, perfume, laundry detergent and dishwashing.

Because the oval bottles have a larger surface that can be used for product feature demonstration, also, its lively shape makes it a popular and makes them common packaging choice.

Automatic Filling and Capping Machine Line is designed for oval bottles which easy to overturn while conveying, providing stable and balanced transportation for many sizes/heights of bottles. The filling station has multiple filling nozzles and dual-track conveying, which are designed for maintaining continuous production and increasing efficiency.

Also, the distance between the two bottles remains proper so that there is no interference in the liquid filling procedure. After filling procedure, the bottles will be conveyed to the cap-placing machine, and start automatic cap placing, cap pressing and cap screwing process simultaneously.

The 3-in-1 machine design of cap-sorting, cap-pressing, and cap-screwing not only shortens the process time but also saves space in the production area.

Automatic Filling and Capping Machine Line will correct the system automatically according to the central spot of the container while doing liquid filling and cap screwing procedure. If the production line is connected to the labeler, the production line can correct or maintain the specific transporting angle.

Every mechanism was designed after full consideration of production details, making the production process fluent and efficient.

How Could The Automatic Filling Capping Line Be Used On Different sizes of Round and Oval bottles?

Automatic Filling and Capping Machine Line can be applied to low to medium-concentrated liquids. In addition, when the container is an oval bottle, not a common round bottle, it would be more challenging to design a full automatic bottle unscrambler, conveyor, filling machine, capping machine, and labeling machine because unlike a common round bottle, the oval one could be more various in dimension and shape.

(Oval bottle has both short and long axes, which causes more variety, so sometimes it cannot use a common design for bottle unscrambling, conveying, positioning, and bottle out-feeding purposes.)

We will customize the filling capping machine design according to the shape of the bottle you’d like to use, providing oval bottle automatic filling capping modules that have the advantage of universal application and can be applied to different sizes of round/oval bottles.

The mechanical design focused on the commonality of the module, providing an easy-changing and simple-to-adjust method that means convenience in operation, and a fully automatic high-speed liquid filling capping production line.

Features

- Automatic Filling and Capping Machine Line is equipped with a threaded-rod conveying device that makes bottle transport more stable and consistent.

- Multiple nozzles, a dual-track liquid filling machine keeps you from wasting time on bottle positioning, and it saves your filling time, which can improve capacity.

- Automatic Filling and Capping Machine Line’s gear pump used on the filling machine meets the hygiene regulations.

- The Module on the instrument can be customized to apply to different bottles.

- Automatic Filling and Capping Machine Line’s filling volume is adjustable, depending on the bottle capacity and bottle mouth diameter.

- Automatic Filling and Capping Machine Line’s memory function lets you save and load the parameter setting easily, simple to do product changeover simple.

- Automatic Filling and Capping Machine Line’s filling nozzle is made of stainless steel, and it has a special ball valve that can prevent liquid dripping.

- Automatic filler capper machine equipped with a high-accuracy Big brand sensor lowers the false detection possibility.

- The machine interface is user-friendly, simple to operate, and can adjust the filling volume and production speed.

- The liquid filling machine is equipped with a dripping-free device under the filling nozzle, avoiding liquid dripping.

- The diving filling nozzle prevents foam from forming when liquid filling.

- Automatic Filling and Capping Machine Line has a flow sensor and a liquid level detection sensor that provide stable filling speed and precise liquid output.

- The cap-sorting, cap-feeding, and cap-placing machine can be customized (for special caps)

- Oval round bottle liquid filling capping machine can be applied to room temperature and low viscosity liquid filling production.

- The capping machine has a no-cap and no-bottle reminder so the operator can monitor the production on time.

- The Automatic Filling and Capping Machine Line has a production capacity counting function that can be used for quantity statistics and daily capacity analysis.

- The filling tube meets the food, pharmaceutical, and biotech industry requirements; there will be no interaction between the tube and liquid.

- The Automatic Filling and Capping Machine Line is easy to adjust and has a precise control system.

- The special vacuum valve can be applied to low to medium-concentration liquid filling.

- Automatic Filling and Capping Machine Line’s Automatic shut-off valve ensures the surplus liquid will flow into the storage tank, and no other recycle equipment is needed.

- Automatic capping machine can use different capping modes according to the cap types and bottle shapes you use.

- Both filling head and capping head are equipped with a hand wheel and a position indicator, which can help the operator to adjust the machine and record the data.

- Automatic Filling and Capping Machine Line has a multi-speed motor-driven conveyor whose speed can be adjusted depending on production requirements.

- The modularized design makes it easy to maintain and can be replaced according to your needs.

- The Automatic Filling and Capping Machine Line is controlled by a PLC, and its counting function ensures the production process.

- The filling line is modularized and can be updated on demand, increasing the production flexibility.

- The whole machine (Automatic Filling and Capping Machine Line) is made of stainless steel and hardened aluminum alloy, which is solid and lasting

- Adjustable base frame and moving wheel.

- The automatic bottle in-feed and out-feed machine can upgrade the line into full automatic production, reducing the manpower requirement.

- Automatic bottle unturned and bottle jam detection function.

Specification

Liquid filling machine (Overflow filling machine)

- Filling speed: Max. 250ml/sec

- Filling range: Max. 5000ml

- Dimension: (L) 2800mm (W) 1500mm (H) 2400mm

- Weight: 560 KG

Capping machine (with cap placer)

- Cap types: common screw caps

- Cap diameter: 25-55mm

- Capping speed: 30-45BPM (depends on the bottle and cap type)

- Dimension: (L) 2500mm (W) 1200mm (H) 1600mm

- Weight: 450 KG

Power and air supply

- Power: 110/220 VAC, 50/60, 1Phase

- Air: 80 PSI/ 3CFM

Option Accessories

- Round bottle labeler

- Bottle outfeed machine

- Temperature-proof and abrasion-proof tubes are available

- Automatic bottle infeed machine