- This machine is suitable for the pharmaceutical, hospital, and food industries to count and fill product suck as capsules, tablets, grain beans, etc.

- Applicable to all kinds of capsules, pills, and tablets with a diameter of 6mm or above and high 3mm or above.

- The counting number can be set to count from 1 to 9999, and the setting is simple

- Dual nozzles are filled in turn, alternating operation, which is in line with the humanized two-handed operation habits

- Counting of different types of products without further adjustment

- Blanking vibration prevents product jams, and the blanking speed can be adjusted

- High-standard food-grade hopper to avoid pollution and residues

- The feeding speed of the turntable can be adjusted according to the diameter of the product to reach the best production capacity

- The output of the container and the counting of pieces can be set

- PLC control program and LCD human-machine interface, easy to set and operate

- Counting different products without changing models and components

- Rotary counting, precise computer detection, high-speed precision counting, and stable operation

- Equipped with a dust collection device to protect the sensor and ensure the accuracy of counting

- Japan's high-precision photoelectric sensor, precision counting.

- Electromagnetic vibration blanking, when the bottle is placed at the outlet, the tablets or capsules pass automatically

- Set the counting speed, and freely set the production speed according to the capacity

- Customized large hopper, reducing the number of refills during production

- Touch screen monitor for real-time monitoring of outputs with a parameter memory function that can memorize multiple production formulas

- Safety protection device with emergency stop button to ensure the safety of operators

- The components in contact between the machine and the product are made of 316 stainless steel, which meets the current cGMP good manufacturing conditions for pharmaceuticals

- The component that contactsthe product can be removed without tools, for easy cleaning and maintenance

Tabletop Tablet Counting Machine (Capsule, Pill, Tablet Counter)

Availability: In StockFeatures

Specifications

- Capsule size: Diameter > 6mm, Height > 3mm

- Tablet size: 2mm ~ 30mm

- Counting speed: 600 ~ 1,000 pcs/min (varied by types and sizes)

- Accuracy: ± 1 tablet

- Bottle size: diameter: 48mm ~ 100 mm/height: 116mm

- Power supply: 110/220VAC, 50/60Hz

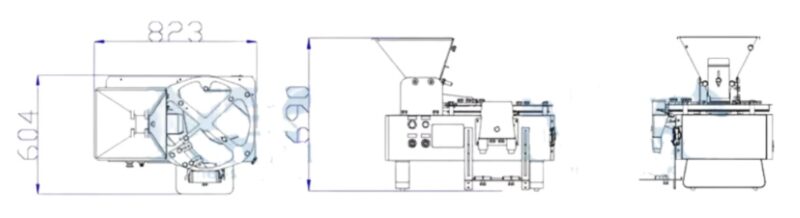

- Machine dimension: (L) 822mm (W) 588mm (H) 739mm

- * Machine dimensions may vary due to adjustments in their design.

Option Accessories

- Automatic bottle infeed system

- Bottle arranging system

- Bottle locating system

- Dust guard

Description

Description

Tabletop Tablet / Capsule Counter TC1000 is designed for high-speed and precision quantitative counting for tablets, soft/hard capsules, and so on. The maximum output is 1000 pieces per minute. TC1000 can set figures to fill your product into containers such as bags and bottles.

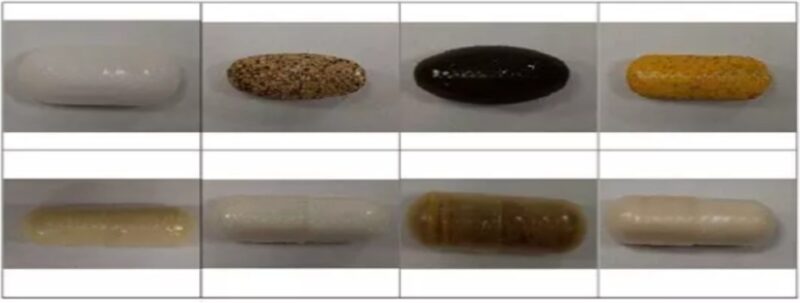

When operating TC1000, put your products in the hopper, the vibration unit will send them into the tempered glass turntable to line up, the photoelectric sensor unit will then fill the products into the container precisely according to the figures set on the control panel. Tabletop Tablet/Capsule Counter is suitable for any regular pattern products, it has a diameter of 6mm or above and a height of 3mm or above. The known product that is suitable for this counter is soft/hard capsules, tablets, chewing gums, star-shaped products, pills, dragees, lozenges, troches, etc…

Dual nozzles have high-speed quantitative counting and can count a variety of products.

The tablet/capsule counting machine has single/dual channel filling modes, which can be set according to production requirements. The fast blanking unit does not jam when the product is counted. The photoelectric sensor can meet high precision quantitative counting, while the glass turntable conveys product through high-speed turning. The double nozzles can fill two containers at once to meet the high efficiency production. The production speed can be adjusted according to the actual product and production capacity to make the production more flexible.

The TC1000 Tabletop Tablet / Capsule Counting machine is suitable for various sizes of products. The vibration frequency and the glass turntable turning speed can be adjusted depending on the products to meet the best production capacity. The control panel of the machine can easily set the counting figures and output. The machine is easily operated, no special training required, one man can complete all operations, and no tools are needed when changing products.

Tabletop Tablet / Capsule Counting machine can be supplied to a hospital pharmacy, small mid-scale biotech company, dietary supplement manufacturer, cosmetic manufacturer, grocery manufacturer, or tablet/capsule manufacturer for counting needed. A single machine can achieve various types of product counting and filling. TC1000 can also be customized with different labeling machines, capping machines, date coders, and other packaging machines into production lines for tablets, capsules, and any products that are suitable for this machine.

Advantages

- Obtained CE certification

- High speed counting and filling, 600-1000 pieces per minute (according to product size)

- Dual nozzles are filled in turn, alternating operation, time-saving, and high-efficiency

- Can count product such as tablets, capsules, pills and screws

- Meet the specifications of current good manufacturing practices (cGMP)

- Can also count products such as candies and chocolates

Application & Advantage

Tabletop Tablet/Capsule Counting Machine applicable product

All kinds of granular/particle products that require counting, such as tablets, capsules, lozenges, film-coated tablets, dragees, soft/hard capsules, pills, peppermint tablets, chewing gum, cod liver oil, candy, chocolate balls, beads, beans, buttons, laundry detergent capsules.

Applicable industry

Pharmaceutical manufacturer, Chinese Pharmaceutical manufacturer, biotechnology companies, dietary supplement manufacturer, cosmetics manufacturer, grocery manufacturer, laboratories, large hospitals, and large pharmacies.

Packing method

Any bottle containers and bag containers.

Q & A

Q1: Can the TC models’ counting machine count soft candy?

A: It depends onthe product’s characteristics. The TC models counting machine is suitable for non-sticky products with a regular shape. If the surface of the product is irregular in shape, sticky, or has sugars that are easy to deliquesce, these products will not be able to roll on the turntable for counting and filling. If your soft candies are similar to capsules, tablets, flakes, and balls, with no stickiness between them, you can use this type of counting machine to fill your product.

Q2: Our counting machine has two kinds of model, s TC and TM. What is the difference, and how to choose between them?

A: Both types of counters are suitable for counting capsules, tablets, pills, and other products. The counting speed of the TC models’ counting machines is faster, and the accuracy and speed performance are optimized when counting products with regular shapes. The TM models of tablet counting machines are slower than the TC models, which are more suitable for products that are fragile and high-priced.

Features

- This machine is suitable for the pharmaceutical, hospital, and food industries to count and fill product suck as capsules, tablets, grain beans, etc.

- Applicable to all kinds of capsules, pills, and tablets with a diameter of 6mm or above and high 3mm or above.

- The counting number can be set to count from 1 to 9999, and the setting is simple

- Dual nozzles are filled in turn, alternating operation, which is in line with the humanized two-handed operation habits

- Counting of different types of products without further adjustment

- Blanking vibration prevents product jams, and the blanking speed can be adjusted

- High-standard food-grade hopper to avoid pollution and residues

- The feeding speed of the turntable can be adjusted according to the diameter of the product to reach the best production capacity

- The output of the container and the counting of pieces can be set

- PLC control program and LCD human-machine interface, easy to set and operate

- Counting different products without changing models and components

- Rotary counting, precise computer detection, high-speed precision counting, and stable operation

- Equipped with a dust collection device to protect the sensor and ensure the accuracy of counting

- Japan’s high-precision photoelectric sensor, precision counting.

- Electromagnetic vibration blanking, when the bottle is placed at the outlet, the tablets or capsules pass automatically

- Set the counting speed, and freely set the production speed according to the capacity

- Customized large hopper, reducing the number of refills during production

- Touch screen monitor for real-time monitoring of outputs with a parameter memory function that can memorize multiple production formulas

- Safety protection device with emergency stop button to ensure the safety of operators

- The components in contact between the machine and the product are made of 316 stainless steel, which meets the current cGMP good manufacturing conditions for pharmaceuticals

- The component that contactsthe product can be removed without tools, for easy cleaning and maintenance

Specification

- Capsule size: Diameter > 6mm, Height > 3mm

- Tablet size: 2mm ~ 30mm

- Counting speed: 600 ~ 1,000 pcs/min (varied by types and sizes)

- Accuracy: ± 1 tablet

- Bottle size: diameter: 48mm ~ 100 mm/height: 116mm

- Power supply: 110/220VAC, 50/60Hz

- Machine dimension: (L) 822mm (W) 588mm (H) 739mm

- * Machine dimensions may vary due to adjustments in their design.

Option Accessories

- Automatic bottle infeed system

- Bottle arranging system

- Bottle locating system

- Dust guard